Navigate Your Construction Business Efficiently with Top-Quality Aftermarket Construction Parts

Navigate Your Construction Business Efficiently with Top-Quality Aftermarket Construction Parts

Blog Article

Take Full Advantage Of Efficiency: The Benefits of Utilizing Aftermarket Components for Heavy Equipment

In the world of hefty equipment upkeep and optimization, the use of aftermarket components has actually emerged as a tactical selection for lots of sector experts. The decision to incorporate aftermarket parts into heavy machinery raises pertinent concerns around efficiency enhancement, cost-effectiveness, and long-lasting functional effectiveness. As markets remain to look for ways to elevate the functionality and longevity of their heavy tools, the discussion surrounding the benefits of aftermarket components becomes progressively compelling. By discovering the nuances of this alternative method to machinery maintenance, one can discover a realm of opportunities that supply greater than fulfills the eye.

Cost-efficient Option

An affordable approach to preserving heavy equipment is by deciding for aftermarket components, which provide an economical service without jeopardizing quality. Aftermarket parts are manufactured by third-party companies as substitutes for initial equipment supplier (OEM) components. These components are commonly extra budget-friendly than their OEM equivalents because of affordable pricing and reduced brand costs. Regardless of their lower price, aftermarket components undertake extensive screening to satisfy sector criteria and ensure compatibility with different heavy equipment versions.

Wide Range of Options

Furthermore, the schedule of aftermarket parts from multiple suppliers and makers produces an open market that drives technology and quality enhancement - aftermarket construction parts. This competition benefits services by supplying them access to technologically sophisticated parts that may not be readily available from initial devices suppliers (OEMs) By having a variety of aftermarket alternatives to pick from, companies can enhance the performance, performance, and long life of their heavy machinery while keeping prices in control

Improved Efficiency and Effectiveness

Enhancing heavy machinery efficiency and efficiency with the utilization of aftermarket parts is a strategic technique that several services are progressively taking on. By integrating aftermarket parts specifically developed for heavy equipment, companies can considerably enhance the general performance and productivity of their tools. Aftermarket components frequently use innovative modern technology and enhanced products compared to initial devices maker (OEM) components, resulting in enhanced performance levels.

One key element of aftermarket components adding to boosted efficiency is their ability to address details issues or weak points in the original machinery design. This targeted method can lead to far better overall performance, decreased downtime, and boosted functional effectiveness. Additionally, aftermarket parts are her response frequently crafted to provide much better toughness and longevity, additional increasing the machinery's performance over an extended duration.

In addition, aftermarket components can assist maximize the machinery's fuel intake, causing cost financial savings and ecological benefits. By fine-tuning the tools's elements, companies can achieve greater levels of effectiveness, equating right into improved profitability and sustainability in the lengthy run. Finally, leveraging aftermarket components to boost hefty equipment performance and effectiveness can provide a competitive edge in today's requiring commercial landscape.

Increased Customization Opportunities

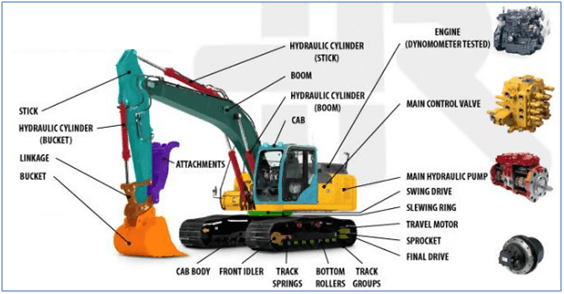

Structure upon the improved performance and efficiency attained through aftermarket parts, next page hefty machinery operators can now check out raised modification opportunities to further enhance their equipment. By incorporating aftermarket parts that cater to particular requirements, operators can adjust their equipment to do tasks a lot more efficiently and effectively. These modification options array from boosted engine elements to specialized add-ons that deal with distinct task requirements. For instance, drivers can mount custom exhaust systems to improve air flow and boost engine efficiency, or they can choose specialized description buckets and blades that are customized to the type of material being taken care of. In addition, aftermarket parts use the adaptability to change numerous facets of the machinery, such as hydraulic systems, controls, and safety features, enabling for an individualized strategy to equipment optimization. This enhanced modification not just boosts the performance of hefty equipment yet also makes sure that drivers can adjust their tools to meet the details demands of various jobs, eventually causing greater productivity and cost-efficiency.

Extended Equipment Life Expectancy

By making use of aftermarket parts especially made for heavy equipment, devices owners can significantly extend the life of their equipments (aftermarket construction parts). These components can improve the performance of heavy equipment, leading to smoother procedures and reduced wear and tear on crucial components.

Regular upkeep and timely substitute of worn-out parts are vital methods to expand the lifespan of heavy machinery. Aftermarket parts offer a cost-effective service contrasted to initial devices maker (OEM) components, permitting devices owners to maintain their machines at a reduced expense without endangering quality. Furthermore, the schedule of a vast array of aftermarket parts makes it much easier to discover suitable substitutes for numerous equipment versions and brands, even more supporting the long life of heavy devices. Eventually, spending in aftermarket components can lead to considerable expense financial savings and raised efficiency by keeping heavy machinery functional for longer durations.

Verdict

In conclusion, making use of aftermarket components for heavy machinery uses an economical solution with a broad variety of alternatives that can enhance efficiency and efficiency. These components also permit boosted modification opportunities and can add to extending the life expectancy of the machinery. Generally, integrating aftermarket parts into hefty equipment repair and maintenance methods can optimize performance and maximize functional end results.

Aftermarket components are produced by third-party business as replacements for original tools manufacturer (OEM) parts. Furthermore, aftermarket parts come in various price features, arrays, and high qualities, allowing organizations to select the components that ideal fit their spending plan and performance demands.

Aftermarket components typically offer innovative technology and enhanced materials compared to initial equipment maker (OEM) parts, leading to improved efficiency levels.

Report this page